| Item | Specification |

|---|---|

| Machine Type | 990 Corrugated Roof Panel Roll Forming Machine |

| Raw Material | Galvanized Steel, PPGI, Aluminum |

| Material Thickness | 0.3 – 0.8 mm |

| Effective Width | 990 mm |

| Forming Speed | 10 – 20 m/min |

| Control System | PLC Automatic Control |

| Cutting System | Hydraulic Cutting |

| Certification | CE, ISO |

Corrugated roofing sheet is a large category of roofing sheet. It is very popular in the roofing sheet market.

Our corrugated roofing sheet machine can quickly produce high-quality 990 corrugated roofing sheets.

| Technical Item | Specification |

|---|---|

| Application | Corrugated Roofing Sheet Production |

| Raw Material | Galvanized Steel (GI), Pre-painted Steel (PPGI), Aluminum |

| Material Thickness | 0.3 – 0.8 mm |

| Coil Width | 1220 mm (according to profile design) |

| Effective Panel Width | 990 mm |

| Profile Type | Corrugated (wavy type) |

| Forming Speed | 10 – 20 m/min |

| Roller Stations | 16 – 22 stations |

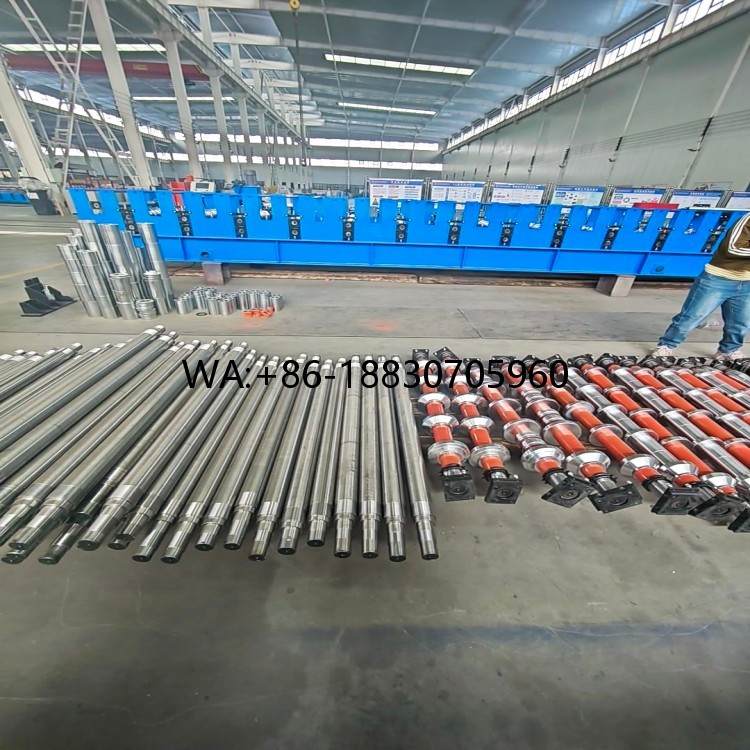

| Shaft Diameter | 70 mm |

| Roller Material | GCr15, heat treated and hard chrome plated |

| Main Motor Power | 5.5 – 7.5 kW |

| Hydraulic Power | 4 – 5.5 kW |

| Cutting System | Hydraulic Post-cutting |

| Control System | PLC (Siemens / Delta / Schneider options) |

| Voltage | 380V / 50Hz / 3 Phase (customizable) |

| Machine Frame | Welded Steel Structure, Heavy-duty Frame |

| Certifications | CE, ISO9001 |

The machine frame is made of very thick plates to make the machine smoother and stronger,

reduce vibration and noise during operation, and increase the life of the machine, making it durable.

The rollers and shafts of the machine are all produced in our factory,

which ensures the quality while allowing customers to buy the machine at a more advantageous price.

The machine is controlled by PLC, which is complete and easy to understand.

Customizable language is available